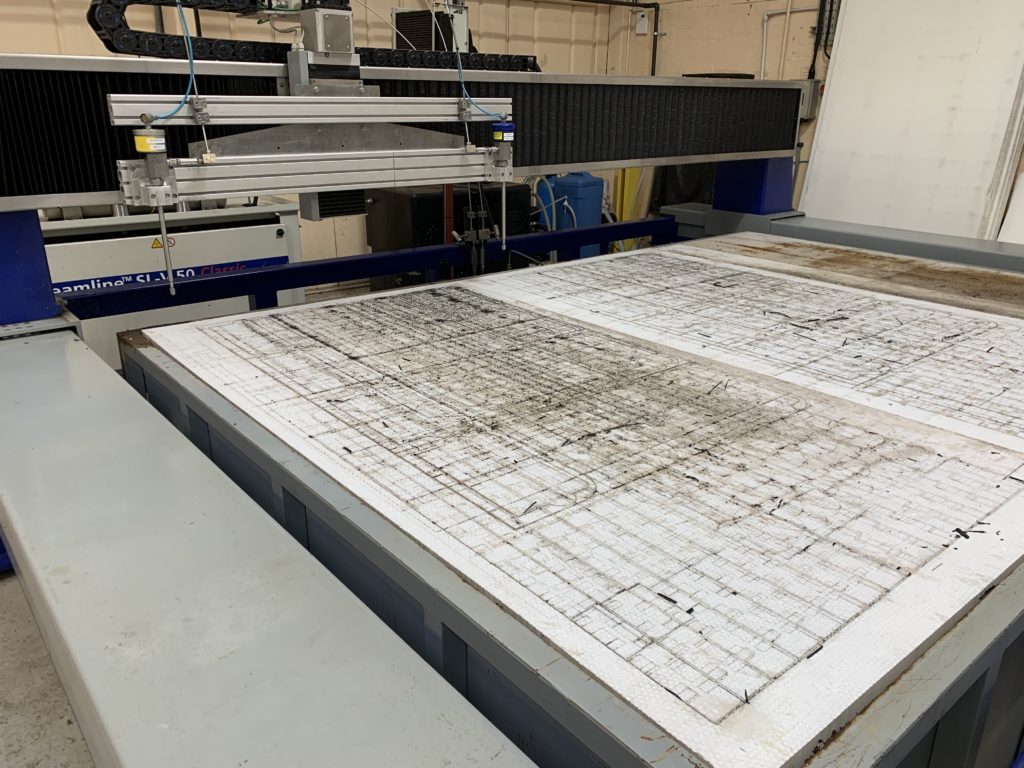

FOAM WATER JET CUTTING

Waterjet cutting is one off the best solutions for cutting foam. Due to its ultra-fine water, it is able to cut this delicate material without compromising its integrity.

Edges are cut clean and precise. Whereas other methods of cutting can lead to problems such concavity, crushing and tearing, there is no distortion or degradation of material when you use our waterjet cutting service.

No matter what shape you need to cut your foam into, our waterjet cutter can handle it thanks to the high-pressure cutting beam which is a mere 0.2mm (0.008”) in diameter. The more traditional approaches to cutting foam, we also have many die cutting machine which are great for fact larger volume jobs but like everything has its limitations, water jet cutting is less limited in terms of the thickness of the foam they can deal with; in contrast, our waterjet cutter is adept at cutting foam up to 200mm in thickness without causing any detrimental effects such as deformation or concaving.

Another obvious advantage of using waterjet cutting on foam products is the ease of use and cost-effectiveness and no need for tooling. The waterjet cutter can work straight from a CAD drawing;, which means you’ll save time and money on short runs and one offs. The waterjet’s unrivalled precision and versatility means it can cut foam for a multitude of purposes such as foams packaging, foam products or gaskets